+86-21-51093066 Specialized in the manufacture of chemical machinery and equipment for 20 years

language

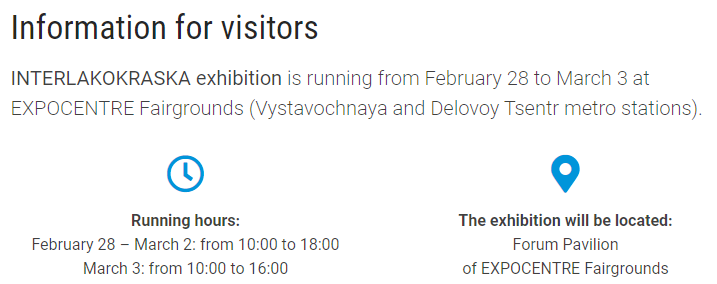

INTERLAKOKRASKA 2023 27TH INTERNATIONAL EXHIBITION FOR PAINTS AND COATINGS

Feb 01, 2023

Interlakokraska is the largest industry project with more than 20 years of history, which has gained prestige among market players. The exhibition is attended by leading Russian and world manufacturers of paints and varnishes and coatings, raw materials, equipment and technologies for their production.

The exhibition is held with the support of the Ministry of Industry and Trade of the Russian Federation, the Russian Union of Chemists, the Russian Chemical Society named by D.I. Mendeleev, Federal State Unitary Enterprise STC Himvest, Scientific Research Institute of Technical and Economic Research in the Chemical Complex (NIITEKHIM), Association Tsentrlak, Association of Paint Quality, under auspices of the Chamber of Commerce and Industry of the Russian Federation.

Paintworks consumers, including representatives of the construction industry, the chemical and oil and gas complexes, woodworking and furniture manufacturing, the automotive industry, aircraft construction and shipbuilding, show high interest in the exhibition.

The subject matter of the exhibition is of interest to a significant circle of specialists due to the demonstration of a wide range of novelties in the field of paint and varnish production. The exhibition presents materials for the treatment of various surfaces, raw materials for all types of paintwork materials, equipment for the production of coatings and application of paintwork materials, dosing and washing equipment, systems for cleaning and processing waste and much more.

Booth No: FC060

Characteristics

• High flux—technology imported from Germany:static centrifugal discharging devices, large discharge area with high output.

• Intelligent double-end mechanical seal: German mechanical seal technology, imported perfluorinated seal ring, can withstand a variety of solvents.

• Grinding area is made of special high wear-resistant alloy steel material ensuring long service life.

• Cooling efficiency: Adopting segmented double spiral channel is more conducive to heat and cold replacement. Cooling efficiency is twice that of ordinary types.

• Grinding efficiency: It is more than 30% higher than ordinary models. The combined disperser group of grinding turbine and dispersion grinding disc can be used to quickly improve the dispersion efficiency. The grinding medium can choose ultra-fine grinding media, which is more efficient.

Application area

Digital printing ink, solvent ink, water-based ink, automobile paint, industrial coating, pigments, color paste, and nanometer materials.

• New design of pin-type grinding components,high grinding efficiency high output, and low energy consumption.

• With smaller length/diameter ratio and higher energy density.

• Using high flux static centrifugal separation sieve, large discharging area, grinding medium no contact with the sieve, no

abrasion, with longer service life.

• Grinding Barrel and grinding rotor adopt forced cooling system, with lower discharging temperature and no influence on sensitive

materials.

• Using top high quality wear-resisting alloy steel, reduce pollution to products. Different materials are optional as per different

products, such as stainless steel, high polymer materials, ceramics, etc.

Principle

The milling basket, containing the grinding bead is lowered into the mill base; the fast circulation of the mill base within the milling basket is generated by the dispersing disc and integrated pump wheel,and a very narrow particle size distribution can be achieved very quickly.

Characteristics

• Suita for producing small batch product and middle test. Dispersing and grinding are finished in one machine and one container, no

need extra pumps, piping, valves etc .

• Easy cleaning, no residues, convenient product replacement.

• Little grinding media required.Excellent grinding efficience and effect.

• Double-walled container for cooling and heating.

• Modular design of parts make it much more convenient to disassemble, maintain and overhaul, almost no need of professional maintainer.

-

BASKET MILL

-

Laboratory equipment

-

Mixer

-

Mixing Kettle

-

Sand mill

-

ISO9001

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Apr 25, 2024

WELCOME TO Turkcoat & PaintIstanbul 2024

Mar 18, 2024

WELCOME TO Middle East Coatings Show, MECS

Feb 23, 2024

PAKISTANO COATING SHOW 2024

Feb 22, 2024

INTERLAKOKRASKA 2024

Nov 20, 2023

Welcome to Abrafati 2023